Remote control

Setting up the mass feed

Loading window

Unloading window

Dimensions (L: W: H)

1330x990x1680 mm

Performance

from 100 kg / h

Power (nominal)

15,000 W

Voltage

380 V

Mass

280 kg

Benefits

-

- Easily demountable design.

- High bandwidth.

- Extended auger chamber.

- Extended screw pair.

- Possibility to select the heating medium (hot water / steam).

- Work flow (complete with the Cheddarizer, an optimal result is achieved, temperature drops are minimized, which in turn contributes to the most uniform quality of raw materials).

- Possibility to set the desired fixed weight (from 200 g to 1 kg)

- Frequency converters allow you to adjust the speed of rotation of the augers.

- Reverse auger function.

- IP-65 waterproof for all drives and controllers.

- STOP button (in accordance with labor safety requirements).

- Possibility of additional equipment by means of interchangeable formation modules.

- All parts in contact with the product are made of food grade acid-resistant stainless steel AISI 316.

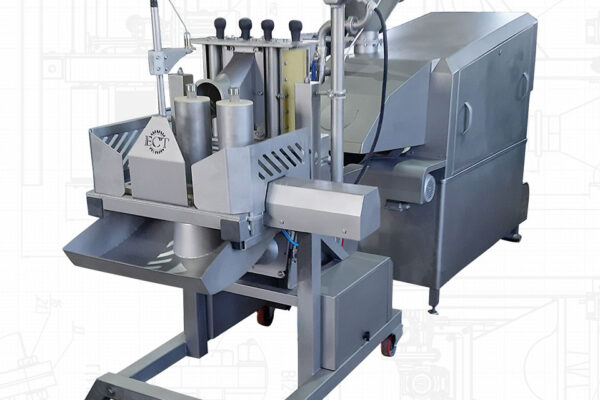

Features of cheese dough dispenser

Formare — DS-2

Cheese dosing unit is manufactured according to individual features and preferences

| Title | Value |

|---|---|

| Loading | up to 60 kg |

| Rated power | 15 kW |

| Air pressure (min-max) | 6 bar |

| Overall dimensions (LxWxH) | 1330x990x1680 mm |

| Weight | 280 kg |

Products that can be manufactured on

cheese dispenser Formare — DS-2

Each type of product has a different formulation

Chechil

Suluguni

Mozzarella

Cachocavallo

Halloumi

Scamorza

Mascarpone

Pizza Cheese (Pizza Cheese)

Our customers

Large producers of cheese and dairy products