Raw material discharge pipe

Remote control

Raw material loading window

Pressure gauge

Dimensions (LxWxH)

2600х820х1500 mm

One-time loading

100-250 kg

Power (rated)

2000 W

Pressure

2 bar

Weight

265 kg

The machine is made of stainless steel AISI 304, designed to transport the cheese mass.

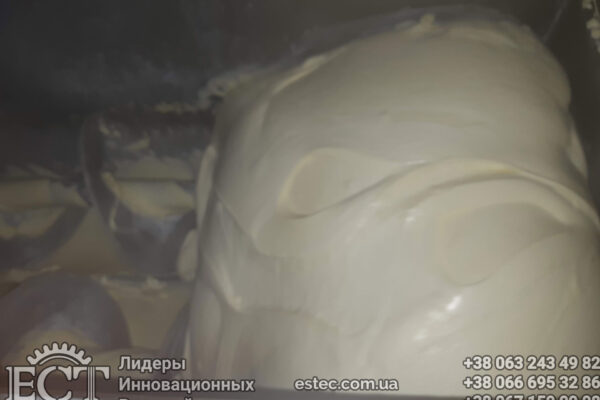

The cheese mass produced is placed in a hopper with two counter-rotating screws at the base, which feed the cheese mass into the extruder tube.

The chamber of the machine housing is heated to maintain a constant temperature in the product during the mixing process, and the walls in contact with the product are coated with a protective coating. The piping rotates at 360 degrees, which allows multiple filling machines to be filled at the same time.

The extruder compensates for the temperature difference between the top and bottom layer of cheese mass.

Inviare Extruder

Cheese melting unit is manufactured according to individual features and preferences

| Name | Value |

|---|---|

| Pressure | 2 bar |

| Capacity | up to 250 kg |

| Rated power | 2 kW |

| Overall dimensions (LxWxH) | 2600х820х1500 mm |

| Weight | 265 kg |

Inviare Extruder

participates in the production of such products

Each type of product utilizes a different technology and formulation

Types of cheese

- Mozzarella

- Feta

- Suluguni

- Chechil

- Scamorza

- Provolone

Cottage cheese products

- Philadelphia

- Cheese desserts

- Thermized desserts

Whizzed cheeses

- Pizza Cheese

- Pieces (beam, bar, triangle)

- Paste-like (cheese in cups)

- Smoked (loafs, sausage cheeses)

Our customers

Large producers of cheese and dairy products